Mandate

- AC&VSD’s mandate of providing Air-conditioning and ventilation services to the centre is met by effective operation and maintenance of Central Water Chilling plant, standalone AC plants, package air-conditioning systems, variable refrigerant flow systems and operation of window/split-ACs. The total design load for air-conditioning and ventilation services of the centre is about 5635 TR.

- Central Water Chilling Plant (CWCP-1) is responsible for providing round the clock air conditioning and ventilation services to RCL, RDL, RML, Computer centre and various buildings & laboratories of IGCAR. There are six numbers of 550TR capacity centrifugal chillers to cater the loads with operating strategy of 4 working, one hot standby and one unit as maintenance standby. It comprises of energy efficient, eco-friendly centrifugal chillers and allied accessories like condenser water pumps, chilled water pumps, cooling towers, booster pumps, underground chilled water piping networks upto 1.5 kms and air handling units.

- 2 MIGD SEA WATER DE-SALINATION PLANT

To meet the growing need of potable water for DAE units at Kalpakkam, a sea water Reverse osmosis desalination plant (SWRO) with a capacity of 2 Million Imperial Gallons per Day (2MIGD)

Achievements

Erection, testing and commissioning of 2 x 750 TR centrifugal chiller at CWCP-II.

- 2 Nos. 750 TR capacity energy efficient centrifugal chiller were installed and commissioned with chilled water pumps, condenser cooling water pumps, cooling towers and associated piping network. Provision of adding 2 more centrifugal chiller in future are also included in the design.

- On 13th October 2021 Dr. B Venkatraman, Outstanding Scientist & Director, IGCAR has dedicated 750 TR centrifugal chiller in Central Water Chilling Plant-II to the Centre

Erection, testing and commissioning of 16 Ton EOT Crane.

-

A 16 Ton Capacity double Girder EOT crane is installed and commissioned at Central water Chilling Plant-II.

The EOT crane is intended to handle heavy equipment during erection activities and thereafter for day-to-day plant maintenance.

Erection, testing and commissioning of 9 Nos. EOT cranes at various facilities of IGCAR:

EOT cranes and hoists are successfully installed and commissioned at following buildings of IGCAR.

- Engineering Hall-IV [2 x 10 Ton capacity]

Structural Dynamics Lab [20 Ton capacity]

Sodium Technology Complex [25/2 Ton, 10 Ton, 5 Ton]

Head End Facility [40/5 Ton SFP, 20 Ton, 10/2 Ton]

Establishment of 2000TR capacity Central Water Chilling Plant-2 at IGCAR.

- Central Water Chilling Plant-II [CWCP-II] is established by Air-Conditioning & Ventilation System Division [AC&VSD] to augment the central air-conditioning infrastructure of IGCAR. CWCP-II is designed to house 4 Nos. of 750TR water cooled chiller and 3 Nos. of 375TR air cooled chillers. The piping system is designed to take up an operating air-conditioning load of 2000 TR in the future. The new plant will cater to the air-conditioning demand of existing buildings such as Training School and Training Centre, Material Science Laboratory (MSL), Material development laboratory (MDL), Condensed Matter Physical Laboratory (CMPL), Particle Irradiation Facility (PIF), Electronics and Instrumentation Laboratory (EIL), HomiBhabha Building and also to meet the AC loads of buildings with standalone package and unitary AC systems after their useful life.

Re-commissioning of cooling towers at CWCP-I.

- The 16 cells of each 250 TR capacity induced draft cross flow Cooling tower at CWCP-1 was revamped with new PVC fills and new structural items for improving efficiency of cooling towers.

Commissioning of 2 nos of 660TR FRP cooling towers in CWCP-I.

- 2 nos of 660 TR FRP induced draft cross flow cooling towers were added to central water chilling plant-1 for augmenting the condenser cooling circuit for meeting the additional AC loads in future.

Commissioning of MDL- MSL building segment chilled water piping.

- As a part of revamping of underground chilled water piping network, the MSL-MDL segment underground chilled water piping network was resized, re-routed and replaced with pre-insulated chilled water pipes. About 1500 metres of chilled water pipes were replaced including valves and fitting. The piping was extended to provide chilled water to INSOT, Hall-III, SGTF, MTD building in future.

Commissioning of CDO- PIF building segment chilled water piping.

- As a part of revamping of underground chilled water piping network, the CDO-PIF segment underground chilled water piping network was resized and replaced with pre-insulated chilled water pipes. About 1900 metres of chilled water pipes were replaced including valves and fitting. The piping network was extended to provide chilled water to PIF Extension, CMPL, RTSD building in future.

Energy Efficient Air-conditioning system for TS&TC (375 TR), Engg. Hall-IV (50 TR):

- An efficiently controlled and monitored air-conditioning system was installed and commissioned to meet the following requirements.

- Maintain comfort conditions of 24±1°C, 55±5% RH.

- Provision to maintain different comfort conditions in class rooms based on occupancy, seasonal requirement etc.

- The air-conditioning system consists of double skinned air handling units, chilled water pumps with Variable Frequency Drives (VFD) microprecesor controlled Variable Air Volume control dampers (VAV).

Commissioning of FBTR- RML-Computer centre building segment chilled water piping

- The underground chilled water header lines of 450 NB and 350 NB were replaced with new pre-insulated pipes for about 1000 m to save water and energy

Commissioning of Desalination Plant

- 2 MIGD Sea Water Reverse Osmosis (SWRO) Desalination Plant was commissioned and put into successful operation to meet the water requirement of DAE facilities at Kalpakkam.

Expertise

- AC&VSD’s mandate of providing Air-conditioning and ventilation services to the centre is met by effective operation and maintenance of Central Water Chilling plant, standalone AC plants, package air-conditioning systems, variable refrigerant flow systems and operation of window/split-ACs. The total design load for air-conditioning and ventilation services of the centre is about 5635 TR.

- Central Water Chilling Plant (CWCP-1) is responsible for providing round the clock air conditioning and ventilation services to RCL, RDL, RML, Computer centre and various buildings & laboratories of IGCAR. There are six numbers of 550TR capacity centrifugal chillers to cater the loads with operating strategy of 4 working, one hot standby and one unit as maintenance standby. It comprises of energy efficient, eco-friendly centrifugal chillers and allied accessories like condenser water pumps, chilled water pumps, cooling towers, booster pumps, underground chilled water piping networks upto 1.5 kms and air handling units.

- 2MIGD SWRO

To meet the growing need of potable water for DAE units at Kalpakkam, a sea water Reverse osmosis desalination plant (SWRO) with a capacity of 2 Million Imperial Gallons per Day (2MIGD) was constructed, in the year 2 The 2 MGD plant is designed with the state of art technology to meet the variable operational requirements of 25 %, 50%, 75% and 100% of the plant capacity. The commissioning of 2MGD plant was completed at the end of 2015.The plant has been in continuous operation since January 2016. 2MIGD SWRO plant produces of potable water confirming to IS 10500 drinking water standard with Specific Energy Consumption (SEC) in the range of 3.3 - 4.8 kWh/m3.

Infrastructure/Facilities

6 nos of 500/550 TR capacity Centrifugal Chiller installed in CWCP-1

Dynamic balancing facility at CWCP

2 nos. of 750TR capacity centrifugal chiller installed at CWCP-II

Pump room in CWCP- II

Cooling towers at CWCP-II

HT and LT panels of CWCP-II

4 Nos. Of 292 m3/hr (45 KW) Capacity Centrifugal Pumps to pump the Raw Seawater to Desalination Plant

4 Skids Of 292 m3/hr Multi Media Filtration Facility for Raw Seawater

4 Skids of 292 m3/hr Poly ether Sulphone Ultra Filtration (UF) Facility

4 Skids of 95 m3/hr Capacity Seawater Reverse Osmosis TFC of Polyamide Membrane Facility (RO - 1 & 2)

Ariel view of Central Water Chilling Plant – I

15TR capacity air-handling unit installed in Ground floor

Package units installed at IDEAS Lab

Multisplit AC installed at VVIP dining

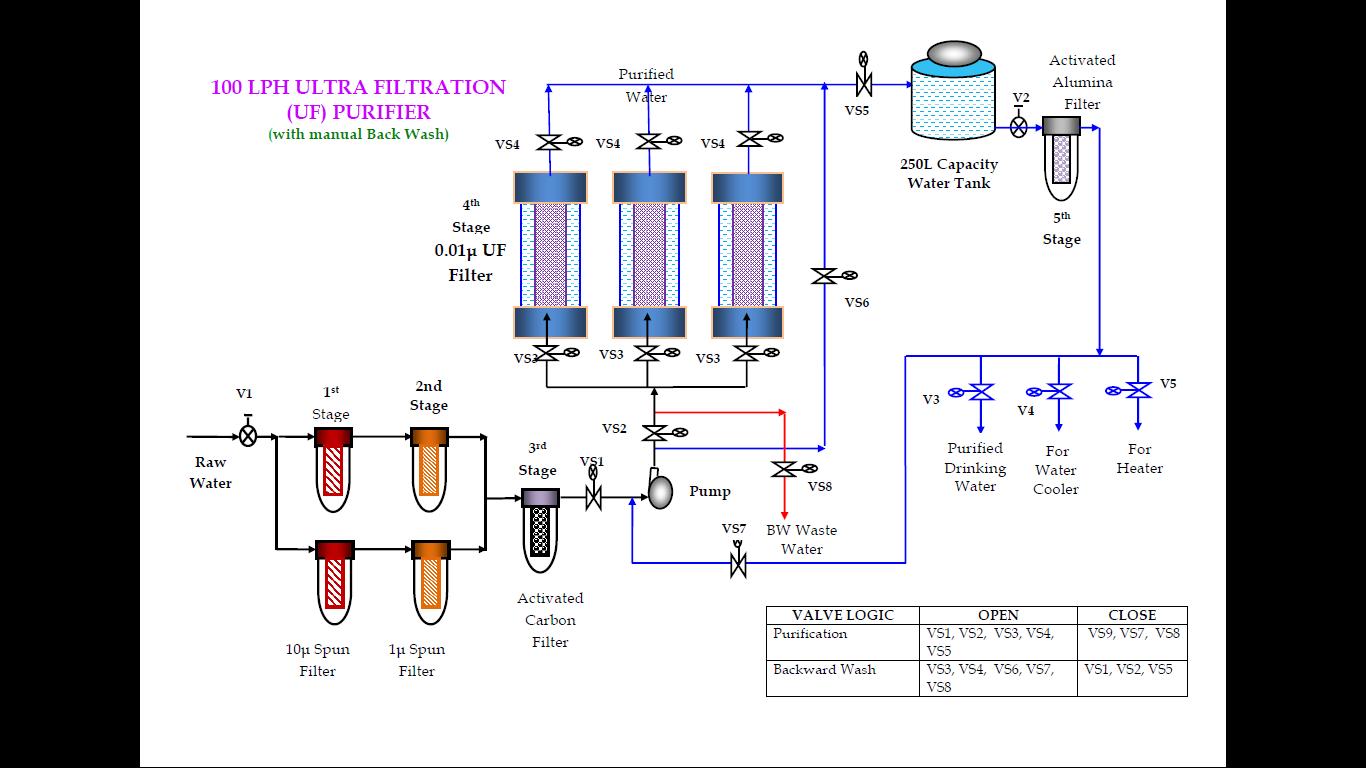

Augmenting AC system at Convention Centre, AnupuramIn-house designed 100 lph Ultra Filtration Water Purifier