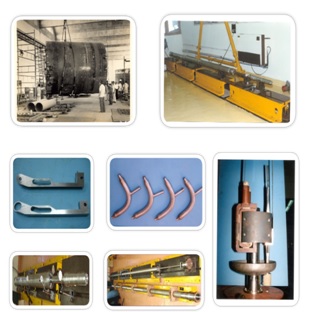

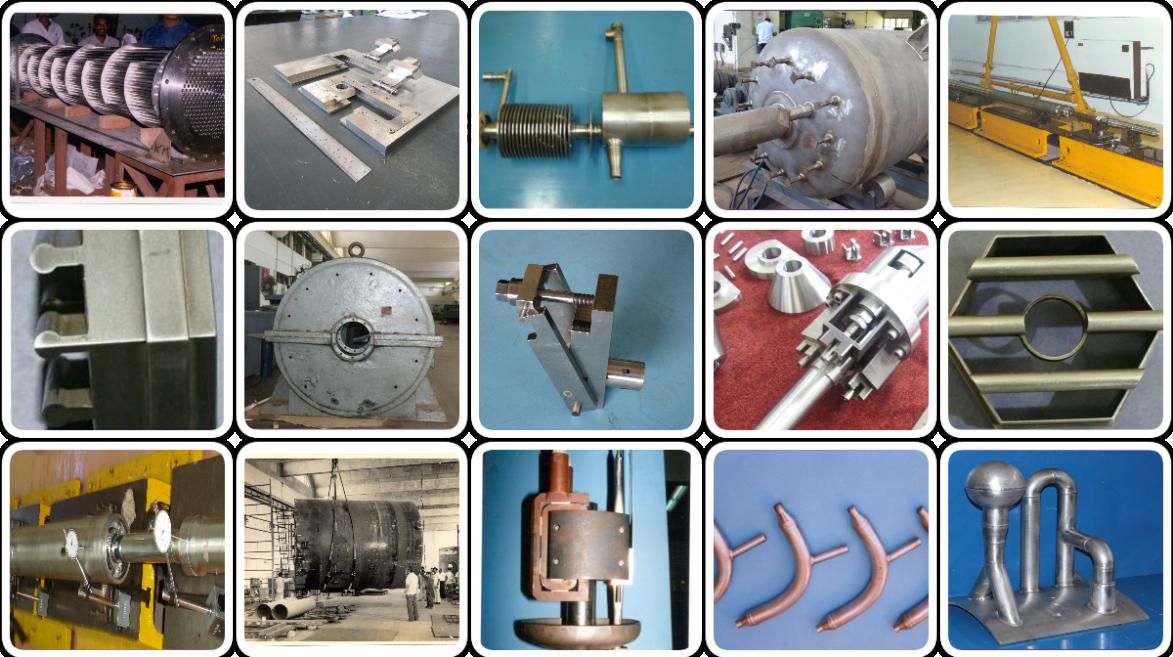

| Machining | Welding, forming and Fabrication | Inspection |

|---|---|---|

| Lathes (Centre, Horizontal / Vertical Turret) | Plate Rolling Machine | Nikon Measuroscope |

| Milling Machine (Vertical, Univerasal, double column) | NC Pipe Bending Machine | CNC 3 axis Coordinate Measuring Machine |

| Drilling Machines (Radial, Column) | Vertical & Horizontal Band Saw | Profile Projector |

| Horizontal Boring Machine | Double Band Saw | XRF Analyser |

| Slotting, Shaping, Planning | Shearing Machine | CMM with Laser Probes |

| Surface and Cylindrical Grinders | Press Brake | Electronic Universal Testing Machine |

| Tool and Cutter Grinders | Heat Treatment Furnaces | Digital Vernier Height gauge |

| Vertical Honing Machine | Welding Machines - TIG, MIG, PTAW, SMAW | CNC Surface Roughness and Profile Measurement Machine |

| CNC EDM Wire Cut and Spark Erosion | Automatic GTAW Machine | Bend Testing |

| Vertical and Horizontal CNC Machining Centres | PTAW Hard facing Machine | Digital Hardness Testing Machine |

| CNC Milling, CNC Lathe | Spot welding Machine | Video Boroscope |

| CNC Turn-Mill Centre | CNC Abrasive Water Jet Cutting Machine | Digital 3 pin Deep Bore Diameter Measurement |

| CNC Drilling and Tapping | CNC Plasma cutting Machine | CNC Vision Measuring System |

| Machining | Welding, forming and Fabrication | Inspection |

|---|---|---|

| Diameter : 3 mm to 1650 mm | Plate rolling machine : Shells of 400mm to 2500 mm long, 3mm to 25 mm thk | Nikon Measuroscope: 2 dimensional measurements; Accuracy 1 micron, Magnification: 100X |

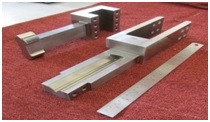

| Length : 5000 mm (Max) | NC Pipe bending machine: Pipe dia: 100 NB max, Thickness: sch 40 max . Bend angle: 180deg | Coordinate CNC 3 Axisl Measuring machine(CMM): Fully Computerised 3D measurements of dimensions, geometrical features like straightness, parallelism, perpendicularity, symmetricity |

| Load : 4000 kg (Max) | Vertical Band & Horizontal band saw : Cutting of metals of any shape | Contouraograph Measurement of Surface profiles : Measurement of labyrinths,curved blades |

| Surface Finish : 0.4 microns | Shearing machine : 12 mm thk; 3000 mm long | Profile projector: Dimensional measurement of profiles |

| Hardness : 60 HRc | Press brake : Bending of rolled sections | CNC Vision Measuring system: Angularity, Flatness, Squareness, Parallelism, Accuracy 0.01 micron |

| Metals : SS, CS, Nonferrous, Stellite, Colmony, Borated Graphite | Heat treatment furnaces : Annealing , hardening, tempering max temp:1200 C | XRF Analyzer : All ferrous and non ferrous metals |

| Planning | Welding machines : Generators, Welding Rectifiers & Inverter | Universal Testing Machine: Testing Of Weld Specimens And Raw Materials r |

| Spark Erosin : irregular profiles, ultrahigh hard materials, miniature sizes | Plasma cutting machine : Cutting of SS and nonferrous metals Max thk.50 mm | Digital Vernier Height gauge |

High precision CNC Slant Bed Turn Mill Centre

CNC Vertical Machining Centre

CNC abrasive water jet (AWJ) cutting machine

Surface roughness measuring machine

Video Boroscope