Metallurgy & Materials Group

Mandate

Highlights

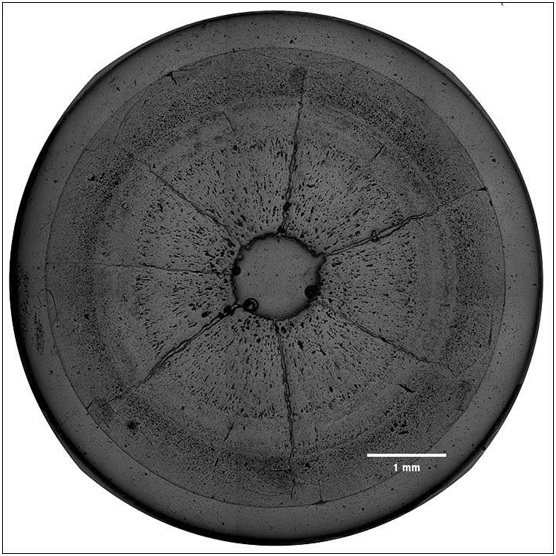

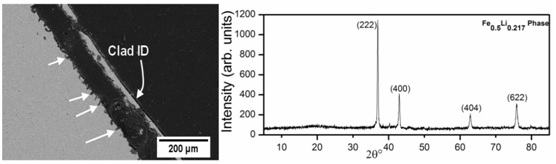

(Left) SEM image showing chemical interaction in SS316L clad of ferroboron test irradiation capsule due to Li formed by (n, α) reaction (Right) XRD profile showing Fe-Li phase in clad ID

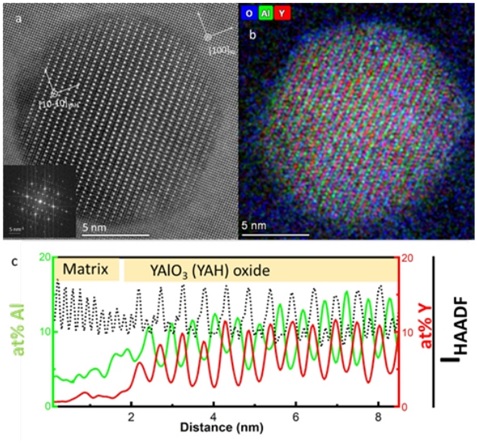

Atomic scale chemical imaging of a dispersoid in dispersion strengthened 617 ODS alloy: (a) STEM-HAADF image of the dispersoid in Ni base SA matrix, (b) EDS chemical imaging of YAlO dispersoid, (c) at% of Al across the dispersoid.

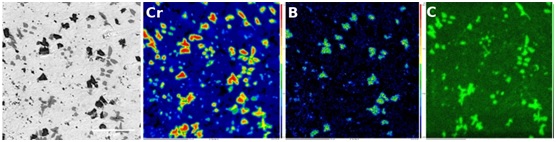

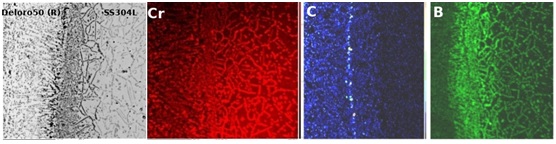

Identification of chromium carbides and borides in additively manufactured Deloro50® components

Precipitation of chromium carbides and borides in Laser deposited Deloro50® on SS 304L comprises grain boundary precipitation on the SS side of the boundary due to faster diffusion of carbon and boron, along with fine precipitates of chromium boride along the grain boundary

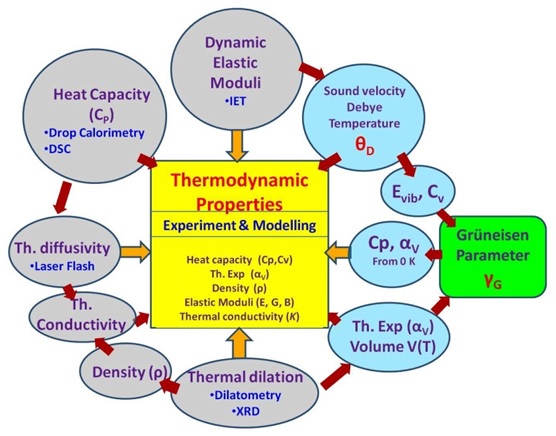

Studies on thermophysical properties of materials through experiment and modelling

Expertise

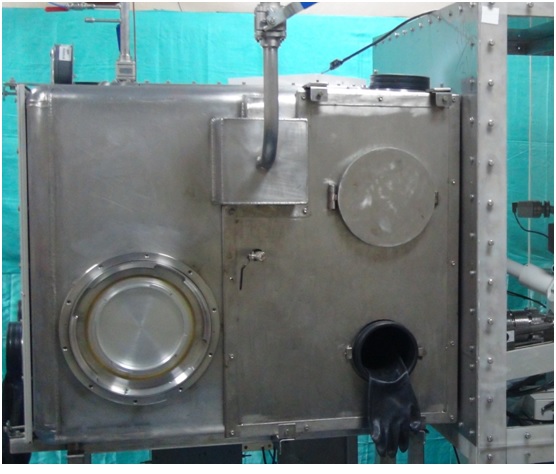

Glovebox adaptation of characterisation instruments for post-irradiation examination

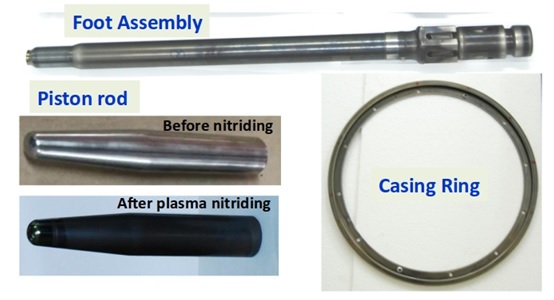

Steel components plasma nitrided to case depths of up to 50µm

Tungsten carbide pellets, 99.8% dense prepared by spark plasma sintering

Achievements

Phase transformations in Steels: determination of TTT / CCT diagrams and deformation tests using a Quench deformation dilatometer