Engineering Services Group

Organization

Mandate

To provide various uninterrupted services such as Electric power supply, Air-conditioning & Ventilation, Intercom telecommunication services, O&M of sea water desalination plant for production of potable water and also manufacturing activities to meet the requirements of this Centre.

To provide various uninterrupted services such as Electric power supply, Air-conditioning & Ventilation, Intercom telecommunication services, O&M of sea water desalination plant for production of potable water and also manufacturing activities to meet the requirements of this Centre.

Highlights

| Division | Milestones |

|---|---|

| ACVSD | |

| Operation of Central Water Chilling Plant- I | |

| Air-conditioning of PIF extension building | |

| Re-engineering of condenser water pumps in CWCP-1: | |

| Re-commissioning of chiller unit # 5 in CWCP-1 | |

| Repair and re-conditioning of cooling towers structures in CWCP | |

| Servicing and load testing of Material Handling Equipment | |

| Augmenting Air-conditioning system at IDEAS lab | |

| Air-conditioning of VVIP Dining Hall, Job shack Lunch Hall and Food Court | |

| Augmenting AC system at Convention Centre, Anupuram | |

| In-house designed 100 lph Ultra Filtration Water Purifier | |

| Establishment of Central Water Chilling Plant- II | |

| Laying of pre-insulated chilled water pipelines in zone-3 CWCP-DFRP segment | |

| 2 MIGD Sea Water De-Salination Plant |

|

| Overall performance of the 2MGD desalination plant is satisfactory in terms of the production of potable water and the quality of water. | |

| Replacement of membranes and installation of Dissolved Air Flotation system in the pre-treatment section to reduce the algae level in the in-feed sea water is being done to improve the performance of the plant further and a tender is floated for this purpose | |

| CWD | |

| Fabrication of Carbon Steel Tank for Storing Soft Water at SGTF | |

| Manufacture of Inlet Water Sub-Headers for FBTR Steam Generator Module | |

| Manufacture and Pressure Testing of Compressed Air Receiver Tank for Steam Generator Test Facility | |

| Characterization of Metallurgical & wear properties of narrow inner diameter Hard faced Austentitic Stainless steel component | |

| Repair / reclamation of Centrifugal Pump Casing of Biological Shield Cooling System of PFBR | |

| Manufacturing of Annular Linear Induction Pumps [ALIPs] for PFBR | |

| Smoothening of sharp corners / edges in Dummy Sub-Assemblies (INNER, B4C and SPL. STEEL SAS) of PFBR | |

| Installation and Commissioning of Electrical Resistance furnace, CNC Vertical Machining Centre 1880, CNC 3- axes Turning Centre, CNC 3 axes Coordinate Measuring Machine (CMM) | |

| Inspection of BHAVINI Grid plate sleeves, FBTR-CRDM – Translation Bellows test setup, Nickel Detector, Inner vessel for STV – 1 & 2 | |

| Manufacturing of Central portion of the Outer tube of PFBR TRANSFER ARM GRIPPER Sub assembly | |

| Machining of IFZ 100 FUEL Sub assembly Connector for FBTR | |

| Machining of Miniature Ring Specimen from very thin Clad Tubes of Fuel Pins | |

| Machining of PFBR Temperature Sensitive Magnetic Switch | |

| Precision Machining of Parts for Orifice Assemblies of FBTR Steam Generator Water Sub-header | |

| ESD | |

| 33 kV Central Switching Station is the nodal Sub-station between two generating stations, Madras Atomic Power Station (MAPS), BHAVINI & Fast Breeder Test Reactor (FBTR) and end users, commissioned in the year 1977 with single 33 kV Incomer from MAPS to feed off-site power requirements of FBTR and allied labs of the then Reactor Research Centre (RRC). | |

| Replacement of 33 kV and 11 kV UG cables between MAPS and IGCAR | |

| Replacement of Station Battery bank at CSS | |

| Drying-up and replacement of 400 kVA Transformer oil at GSB SS, phase-2 | |

| Maintenance of 11 kV outdoor structures for UGC, IFFRM and KKM area | |

| Servicing of 415 Volts, Air circuit breaker carriages of IGCAR Sub-stations by OEMauthorized servicing agent | |

| Replacement of 415 Volts, PCC at RCL Sub-station | |

| Retrofitting & refurbishment of LV system (Phase-1) to improve safety & reliability | |

| Convertion of Fuse DB to PPI MCB DB | |

| Replacement of 415 Volts, PCC at GSB Sub-station, phase-2 |

Expertise

Engineering services Group provides various uninterrupted services such as Electric power supply, Air-conditioning & Ventilation, Intercom telecommunication services, O&M of sea water desalination plant for production of potable water and also manufacturing activities to meet the requirements of this Centre. It has the following divisions Air-conditioning & Ventilation services division, Central Workshop Division and Electrical Services Division.

Achievements

- In line with Industry 4.0, all the 3 divisions of ESG have taken up projects for centralised control and monitoring of processes and systems. Central workshop Integrated Manufacturing (CIM), centralised monitoring of unmanned high voltage substations, centralised control of Air Handling Units (AHUs) are the 3 major elements under this scheme. AC&VSD was awarded first prize in plant category for a clean and tidy plant in Swachhata Pakhwada - 2022 audit.

- Energy saving of 10% w.r.t. the total energy consumed for the systems operated by ESG. Augmenting Solar PV generating capacity to 830 kWp. ESG has set a target of 18% reduction in the energy front and solar generation at 3 MWp.

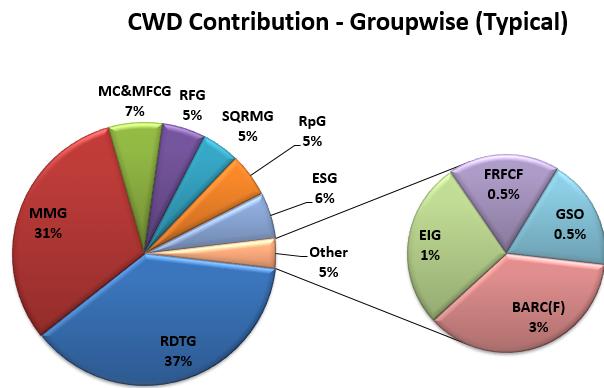

- CWD processes about 450 work orders on average every year and contributed significantly by manufacturing many major components for PFBR, FBTR, IGCAR, BARCF and MAPS. Manufacturing of modified water sub-headers for FBTR steam generator to achieve rated thermal power output of 40MWt, components of Transfer arm, test vessels . With the implementation of CIM and augmentation of automated equipment, CWD is poised for a more efficient sprint to fulfil the manufacturing needs of various groups of IGCAR and DAE in the coming years. A typical user-wise breakup of the CWD work orders is shown below,

Facilities

- Subsequent to establishment of Central Water Chilling Plant II (CWCP II), Chilled water requirement of IGCAR is met by interconnected 2-loop systems leading to better reliability of air conditioning system. Almost 90% of old underground insulated chilled water piping network is replaced resulting in savings of about 5 CMH chilled water.

- Air cooled packaged ACs and packaged chillers system of about 700 TR capacity have been replaced by Central AC system resulting in considerable energy savings. Old AHUs are replaced with energy efficient new AHUs with UVC lamps for disinfection in the post COVID scenario. DFRP air conditioning system is commissioned using chilled water from CWCP replacing erstwhile supply from KARP.

- The Desalination plant is providing quality potable water as per IS:10500 to IGCAR, BARCF, BHAVINI, MAPS etc.. Two skids of indigenous ultra filtration membranes are used for the last one year and their performance is found to be satisfactory. Revamping of Desalination plant has resulted in reduction of specific energy consumption to below design value of 3.18 kWh/ Cu.m.

- A tertiary treatment plant of 20 CMH capacity is being established at CWCP I. The plant will meet the condenser water requirement in the CWCP I from STP output. All the material handling equipment, EOT cranes and hoists of IGCAR are being periodically tested and certified by competent authority for safe operation.

- CWD has been augmented with few major large capacity machines namely, CNC water jet cutting machine, CNC slant bed turn mill centre, CNC vertical milling machine, electrical bogey hearth type heat treatment furnace, CNC coordinate measuring machine etc. to extend its machining, cutting and inspection capabilities and capacity. The new fabrication high bay was made operational in this year resulting in decongestion of the Fabrication Shop.

- Electrical Services Division (ESD) has taken steps in sync with the growing power demand of the centre. The Power system has 4 sources and 20 substations.

- Road Map of CWD for next 10 years Modernization of CWD to enhance overall capacity, precision and complex machining, welding, hard-facing and inspection capabilities. Establishment of facilities for long & large diameter turning & boring, deep hole drilling, deep ID welding and hard-facing. Establishment of Large Capacity Clean Machine Shop, Additive Manufacturing facilities. Refurbishment/Replacement of existing machine tools at end of life.

- Implementation of Central workshop Integrated Manufacturing (CIM) system in line with Industry 4.0 to centrally control entire process planning, manufacturing, inspection and maintenance activities for Rationalization of process flow and seamless two-way interactions with users, Enhanced overall efficiency and productivity, shortening of delivery times, Better documentation to create and store possible intellectual properties.