Materials Chemistry & Metal Fuel Cycle Group

Organization

Mandate

Highlights

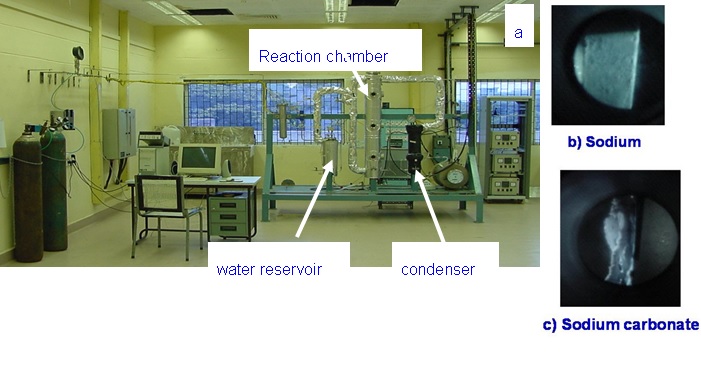

Sodium reacts with water vapour forming sodium hydroxide (NaOH)

The NaOH reacts with carbon dioxide forming mainly sodium bicarbonate

Caustic stress corrosion cracking on SS could be avoided by this method

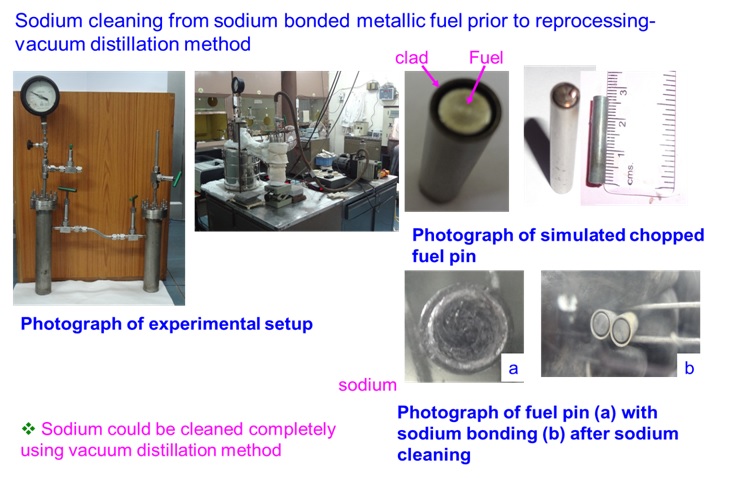

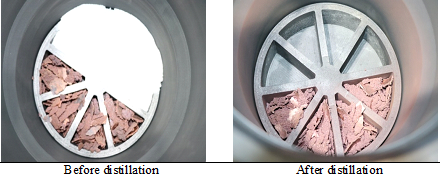

Sodium cleaning from sodium bonded metallic fuel prior to reprocessing-vacuum distillation method

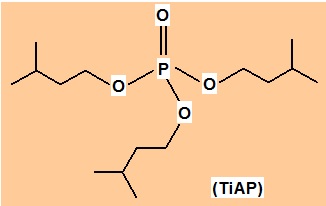

Development of Indigenous solvent for TiAP

Solvent, Tri-isoamyl phosphate (TiAP) developed at IGCAR studies established potential applications for reprocessing fast reactor fuel; alternate to TBP

Indigenous Development of Ion Mobility Spectrometer (IMS) for detection of Narcotics

Chemical Sensors

Cl2 in air / inert ambient

Range : 50 ppb-15 ppm

TLV : 500 ppb

Expertise

Designed and developed salt handling and purification system and demonstrated preparation of LiCl-KCl eutectic mixture with less 50 ppm moisture content by vacuum drying and chlorination at 1 Tonne scale.

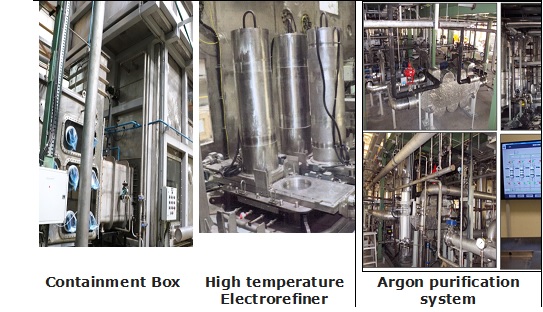

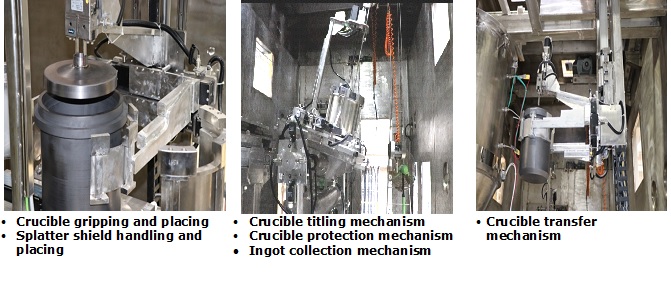

Developed remotely operable devices and specialized remote handling tools for equipment and material transfer operations inside 500 m3 inert atmosphere Containment Box.

Designed, developed and demonstrated operation of inert gas purification system with no purge loss scheme of 500 m3/hr capacity.

Developed vacuum drying and chlorination of LiCl-KCl eutectic salt mixture in an engineering scale.

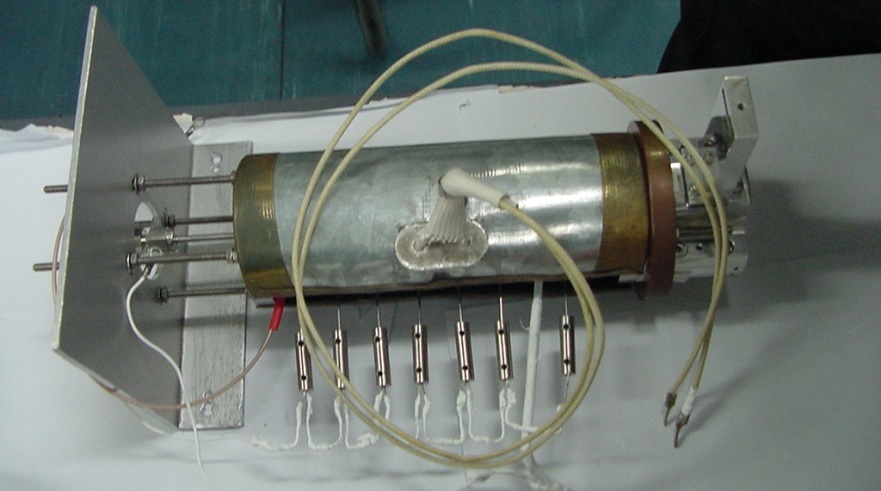

Mock-up induction setup to develop waterless induction heating using solid coil.

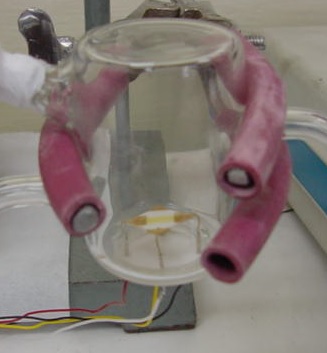

Developed waterless Solid induction coil for salt distillation and metal melting Design, development and demonstration of Molten salt level measurement sensor in collaboration with CFED Design, development and demonstration high temperature measurements in arduous systems

Developed vacuum drying and chlorination of LiCl-KCl eutectic salt mixture in an engineering scale Mock-up induction setup to develop waterless induction heating using solid coil

Achievements

Erection and commissioning of Salt Handling and Purification System and preparation of 1 Tonne of LiCl-KCl eutectic mixture with less than 50 ppm moisture content by vacuum drying and chlorination.

Purified 1000 kg of LiCl-KCl eutectic salt mixture in 25 batches and reduced the moisture level to below 50ppm. Demonstrated pressure control system for 500m3 containment box Demonstrated remote mechanism (pick and place, gripping, tilting) operation of AVDMS inside containment box for more than 50 cycles

Demonstrated distillation of KCl at 950oC and 10 torr pressure in the vacuum chamber housed inside containment box.

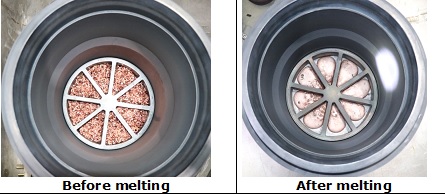

Demonstrated electrorefining of U and U based alloys at 1Kg level in pyro demo facility Demonstrated cathode processing and consolidation of U and U based alloys Li-Cd alloy was prepared in-house, Actinide Draw Down and Back Extraction with U demonstrated Heat capacity measurements on various nuclear fuel, blanket and control rod materials were carried out

Purified 1000kg of LiCl-KCl eutectic salt mixture in 25 batches and reduced the moisture level to below 50ppm. Demonstrated pressure control system for 500m3 containment box Demonstrated remote mechanism (pick and place, gripping, tilting) operation of AVDMS inside containment box for more than 50 cycles

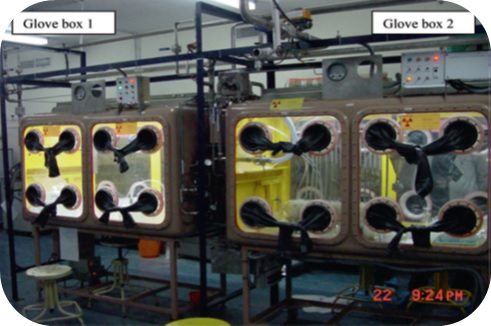

Facilities

A facility for carrying out R&D for pyroprocess technology development has been set up. It consists of Pre-engineered building housing the main systems/equipment with surrounding platforms on two sides for utilities. Inside the building a large argon atmosphere containment box (CB) of 18.5m length, 3.5m width, 6.0m height, is supported on a steel structure at first floor level.

Argon systems, for maintaining pressure, temperature and oxygen & moisture concentration inside the CB, are provided at the ground floor level.

High Temperature Electrorefiner (HTER), for electrorefining, and Automated Vacuum Distillation & Melting System (AVDMS), for cathode product consolidation, are the main process equipments housed inside CB.

A glovebox is attached to CB for transfer of process materials. The building also houses a system for preparation of Eutetic mixture of LiCl-KCl with less than 50 ppm of moisture.

Heat capacity measurements on Pu based nuclear fuels by high temperature drop calorimetry which is integrated with inert atmosphere glove box FIB-SEM with EDX to analyse and characterise various samples

Photograph of the X-ray Diffraction

Photograph of the LIBS