An HEPA filter assembly consists of woven glass fibers or glass fibers and asbestos paper. The medium is corrugated as pleats and framed into metal or plastic holders. The edge of the pleat is pasted on the frame so that air passes through the medium only. These filters are to be tested for its particle filtration efficiency using standard particles of size 0.1 - 0.5 µm at a stipulated flow rate using a Test Rig Facility.

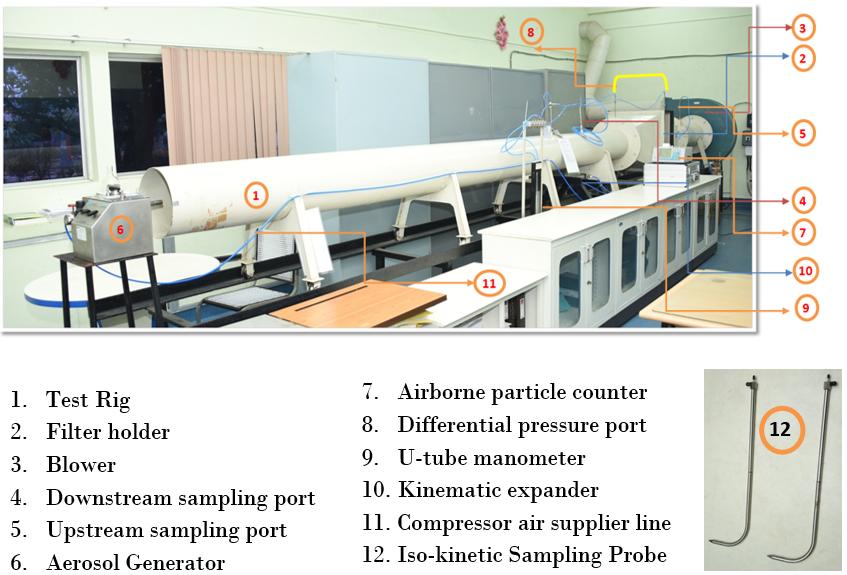

The Test Rig Facility: The test rig facility consists of wind tunnel, HEPA filter assembly holder without air leak, particulate sampling ports and differential pressure measurement ports at the upstream and downstream, a blower, aerosol generator and particle counting system. The rig serves as a test bed for testing of HEPA filter assembly of specific dimensions 610 X 610 X 292 mm with desired configuration with high level of accuracy by adopting standard procedures and protocols. The technology and knowhow of the tailor made Test rig Facility for the evaluation of filtering efficiency of individual HEPA filter assembly was developed by Indira Gandhi Centre for Atomic Research, Kalpakkam and is now available for Technology transfer. The dimensions of the Test Rig can be scaled down to evaluate the standard HEPA filter assembly of lesser dimensions.

The test rig is meant for testing HEPA Filter Assembly having 610 X 610 X 292 mm dimension. The system consists of wind tunnel for the making uniform mixing of challenge aerosols in the upstream, expander sections for mounting filter assembly on both upstream and downstream side, a pneumatic system for holding filter assembly with leak tight, wind tunnel with blower system in the downstream.

The test rig is designed as per British Standard BS2831 which is now modified with latest version, in particular, it is a tailor made unit for HEPA filter assembly testing. The dimension of the upstream side wind tunnel and expander section are very crucial for the uniform mixing of challenge aerosols and face velocity. The location of the sampling ports and isokinetic sampling of challenge aerosols are critical aspect in the design of test rig for effectiveness in evaluation filter assembly. The testing of individual filter assembly is carried out by following IAEA Technical Series-122.

Interested parties with Engineering & Scientific knowledge, good financial background and adequate experience of products manufacturing & fabrication with technical capability in the area of interested technology and having or interested in setting –up facilities for production would be preferred.

Send your Technology Transfer Application form duly filled and signed along with a Demand Draft/Bankers cheque of Rs. 500/- (for Indian entities) or US $50/- (for foreign entities) drawn in favour of “Accounts Officer, IGCAR” as application processing fee on following address:

Note:Applications without processing fee as applicable above of Rs. 500/- or US $50/- for each technology will not be considered.

Click here for Technology Transfer Application Form